NAC strengthened its commitment to protecting the environment through compliance with all mandated environmental programs and through new energy initiatives that will have a long-term impact.

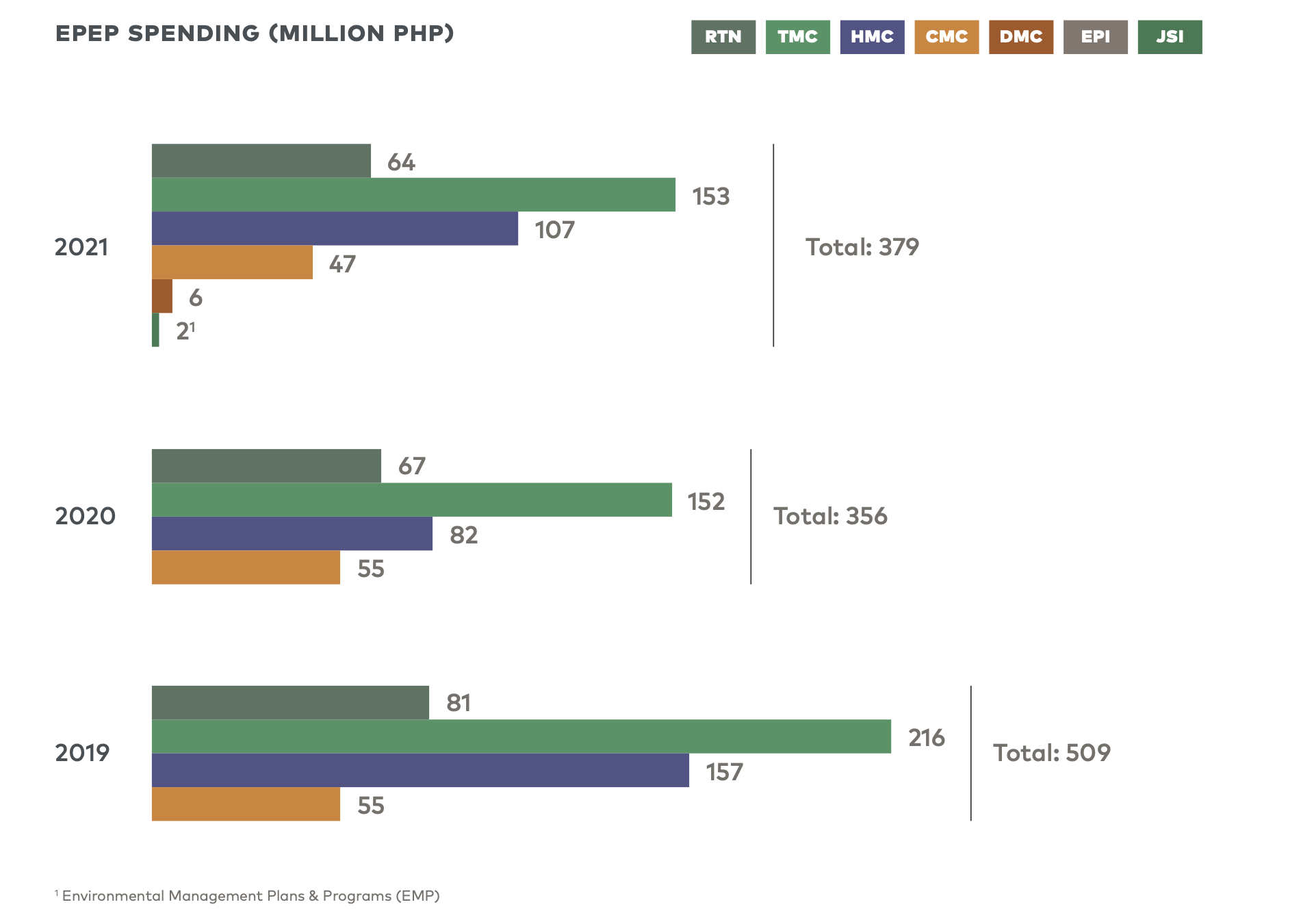

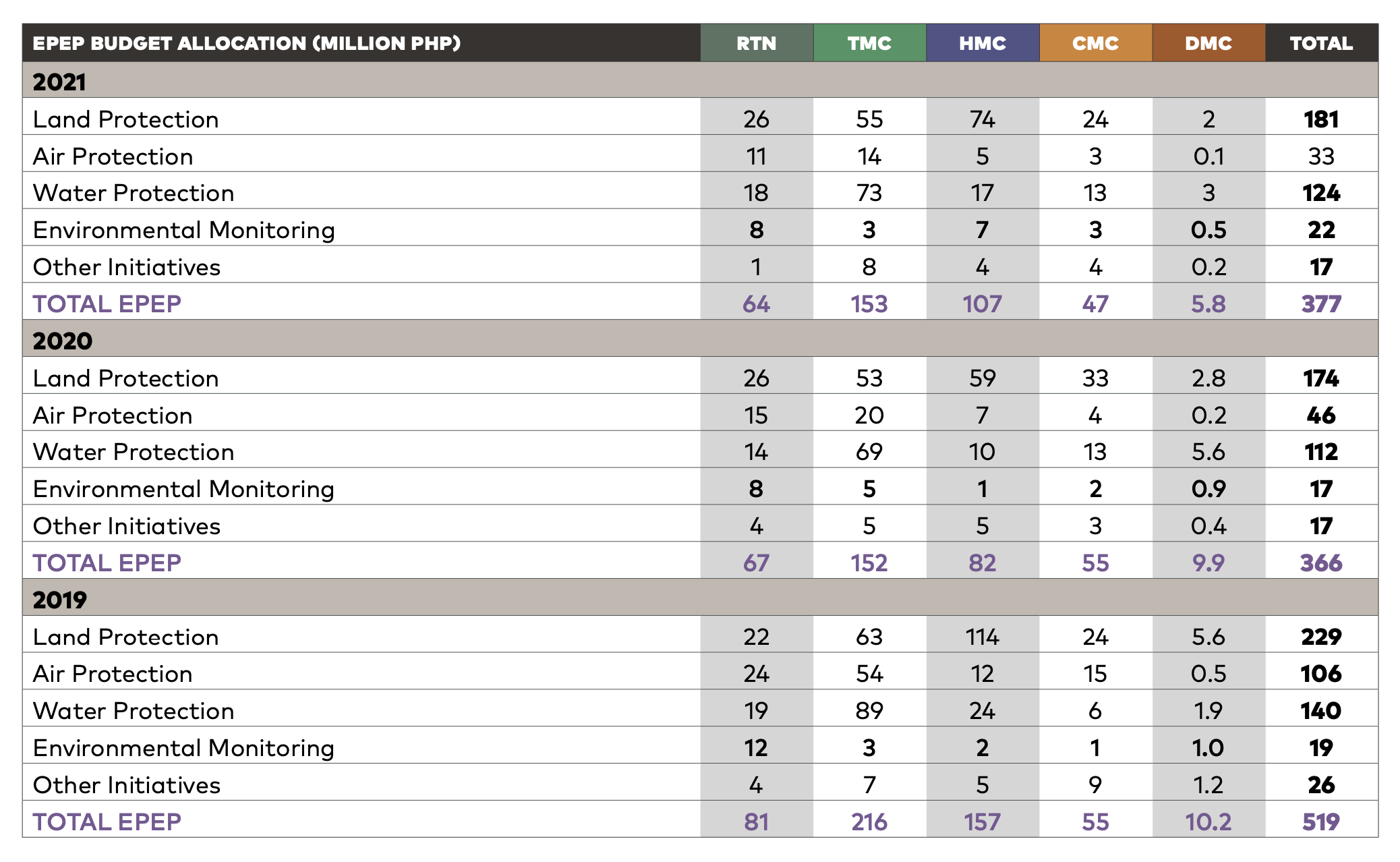

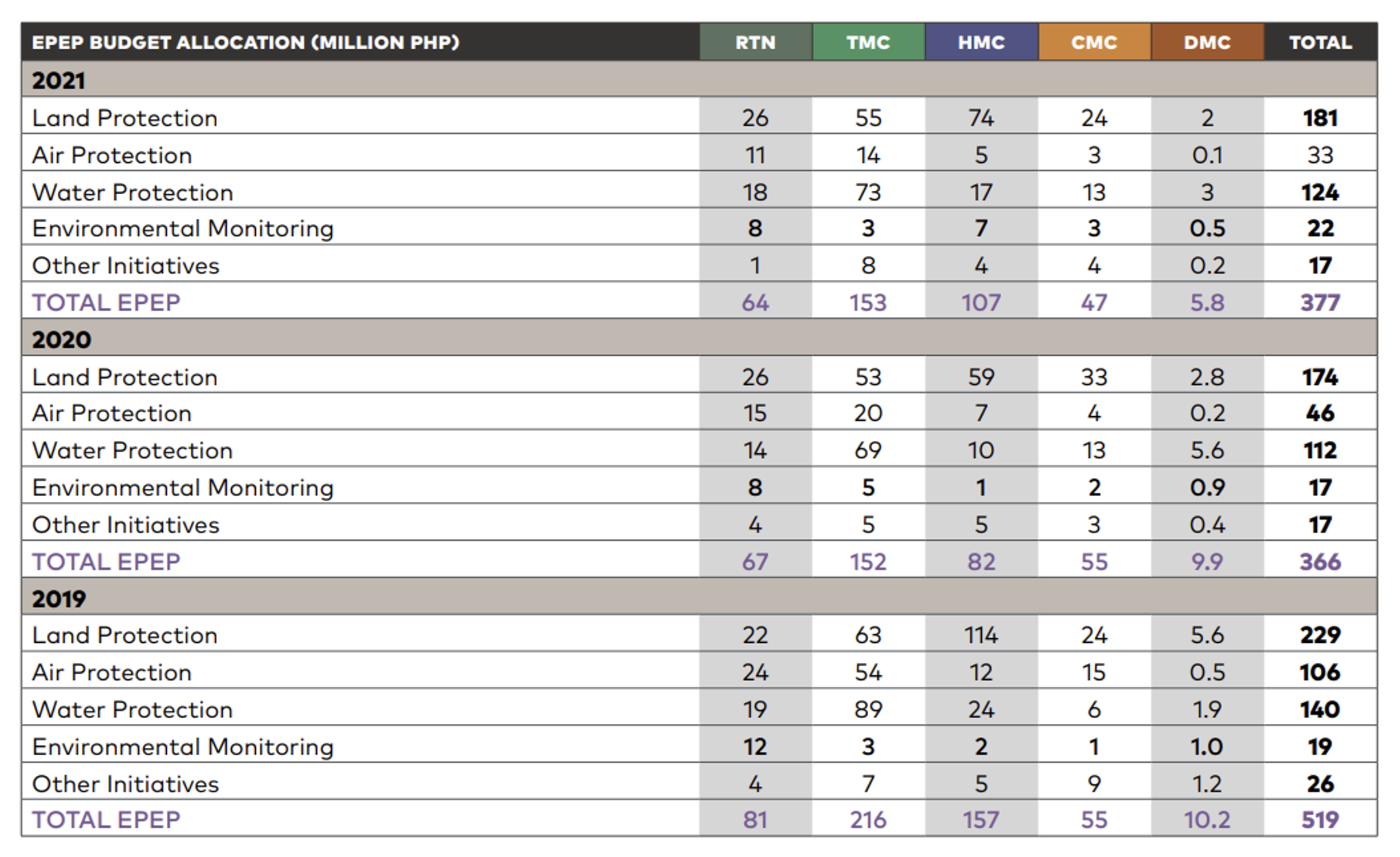

Environmental Protection and Enhancement Programs (EPEPs) are comprehensive and strategic environmental management plans that cover management objectives, criteria, and commitments pertaining to environmental protection and rehabilitation.

These are fully funded for all the operating mines. Each mine’s Annual EPEP funded key programs and initiatives address environmental concerns that includes Land Protection, Air Protection, Water Protection, and Environmental Monitoring. Hence, activities such as rehabilitation of disturbed areas, reforestation, construction and maintenance of environmental facilities, solid waste management, hazardous waste management, air quality monitoring, and preservation of downstream water quality are conducted.

Aside from continuing its existing environmental programs in 2021, CMC has been ahead of the pack in the mining industry in heeding the struggle against the problems caused by sargassum, a brown seaweed locally known as “samo” that are washed ashore.

CMC’s Mine and Environment Protection and Enhancement Office (MEPEO) started experimenting with the viability of using sargassum extracts as fertilizers to be used in the mined-out areas. The experiment led to the development of CMC’s very own Sargassum Liquid Fertilizer (SLF) using the sargassum debris gathered from the shorelines around the mine site.

SLF has now been used as organic fertilizers for seedlings at the CMC nurseries and proved to be successful in growing the crops in the rehabilitated area. Test results show that SLF is rich in nitrogen, phosphorous, and potassium – nutrients that are essential for plants to achieve maximum growth potential.

ISO/EMS Certifications

The operating mining companies of the NAC Group are ISO 14001:2015 (Environmental Management System), ISO 9001:2015 (Quality Management System), and ISO 45001:2018 (Occupational Health and Safety Management System) certified. TMC and HMC’s Manicani nickel mine were endorsed by the international certifying body TÜV Rheinland for these ISO categories. RTN’s ISO certifications for these categories was approved by TÜV Nord; while the ISO certifications of CMC, HMC (for its Tagana-an nickel mine), and DMC for the said categories were validated by the NQA Global Accredited Certification body.

The scope of these ISO certifications covers the following: Mining Operations and Post Mining Activities, Minesite, Campsite, Pier Site/Wharf Facilities including landing craft transports ().

ISO 14001:2015 provides details on the specifications for an environmental management system that a company can use to improve its environmental performance. The intended outcomes include:

- enhancement of environmental performance;

- fulfilment of compliance obligations;

- achieve environmental objectives.

ISO 14001:2015 RTNMC

ISO 14001:2015 TMC

ISO 14001:2015 CMC

ISO 14001:2015 HMC-TNP

ISO 14001:2015 DMC

ISO 14001:2015 HMC-MNP

ISO 9001:2015 specifies requirements for a quality management system when an organization:

- needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements, and

- aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customers and applicable statutory and regulatory requirements.

ISO 9001:2015 RTNMC

ISO 9001:2015 TMC

ISO 9001:2015 CMC

ISO 9001:2015 HMC-TNP

ISO 45001:2018 gives guidance on providing a safe and healthy workplace and implementing the OH&S management system. The intended outcomes include:

- continual improvement of OH&S performance;

- fulfilment of legal requirements and other requirements;

- achievement of OH&S objectives.

ISO 45001:2018 RTNMC

ISO 45001:2018 TMC

ISO 45001:2018 CMC

ISO 45001:2018 HMC-TNP

Environmental Manual

The Mines Environmental Protection and Enhancement Department (MEPED) of the NAC Group follows an environmental procedures manual related to Land Development and Management (Land Use and Waste), Air Quality Monitoring (Emissions), and Water Quality Monitoring (Water Management).

As the NAC Group strengthens its commitment to protecting the environment, these procedures comply with all mandated standards and environmental programs of the Department of Natural Resources (DENR) and its attached agency, the Mines and Geosciences Bureau (MGB).

Mine Rehabilitation. In compliance with DENR Administrative Order 2018-19, the NAC Group complies with the implementation of Temporary Rehabilitation and Final Mine Rehabilitation (Progressive Rehabilitation) to ensure that the maximum disturbed area limit is strictly observed. Once an area is declared as mined out, it is subject to site inspection and evaluation to determine if it should undergo temporary or permanent rehabilitation. A team composed of the Mine Engineering Department, Geology Department, and the MEPED will also determine if the area will need reshaping and backfilling works or if planting activities can already proceed. After the establishment of the rehabilitation area, MEPED conducts quarterly field counts to determine the survival/mortality rate and the growth performance of planted seedlings.

In addition, the NAC Group seeks to comply with the Science Based Target initiative’s (SBTi) Corporate Net-Zero Standard. The main objective is to set a science-based net-zero target consistent with the limiting global temperature rise to 1.5°C. As provided in the manual, the mining companies follow the 2006 IPCC Guidelines for National Greenhouse Gas Inventories in the computation of the their respective emissions.

Silt Management. The procedure for solid waste management (SWM) and hazardous waste management (HWM) specified in the manual follows RA 9003 (Ecological Solid Waste Management Act of 2000) and RA 6969 (Toxic Substances and Hazardous and Nuclear Wastes Control Act of 1990), respectively. The NAC Group strictly implements waste segregation, regular waste collection, proper handling and storage of wastes, and issuance of corrective action for committed violations. It also applies to the mining companies' contractors.

Further, the manual includes the procedures for dredging siltation ponds and total suspended solids (TSS) monitoring.

The manual summarizes the common environmental procedures of the mining companies and was approved by the operating companies' respective managements and NAC's senior management in 2019

NAC Environmental Manual

Below is the individual Environment policy of NAC and its operating mining companies

Environmental Policy NAC

Environmental Policy RTNMC

Environmental Policy TMC

Environmental Policy CMC

Environmental Policy HMC-TNP

Environmental Policy DMC

Environmental Policy HMC-MNP

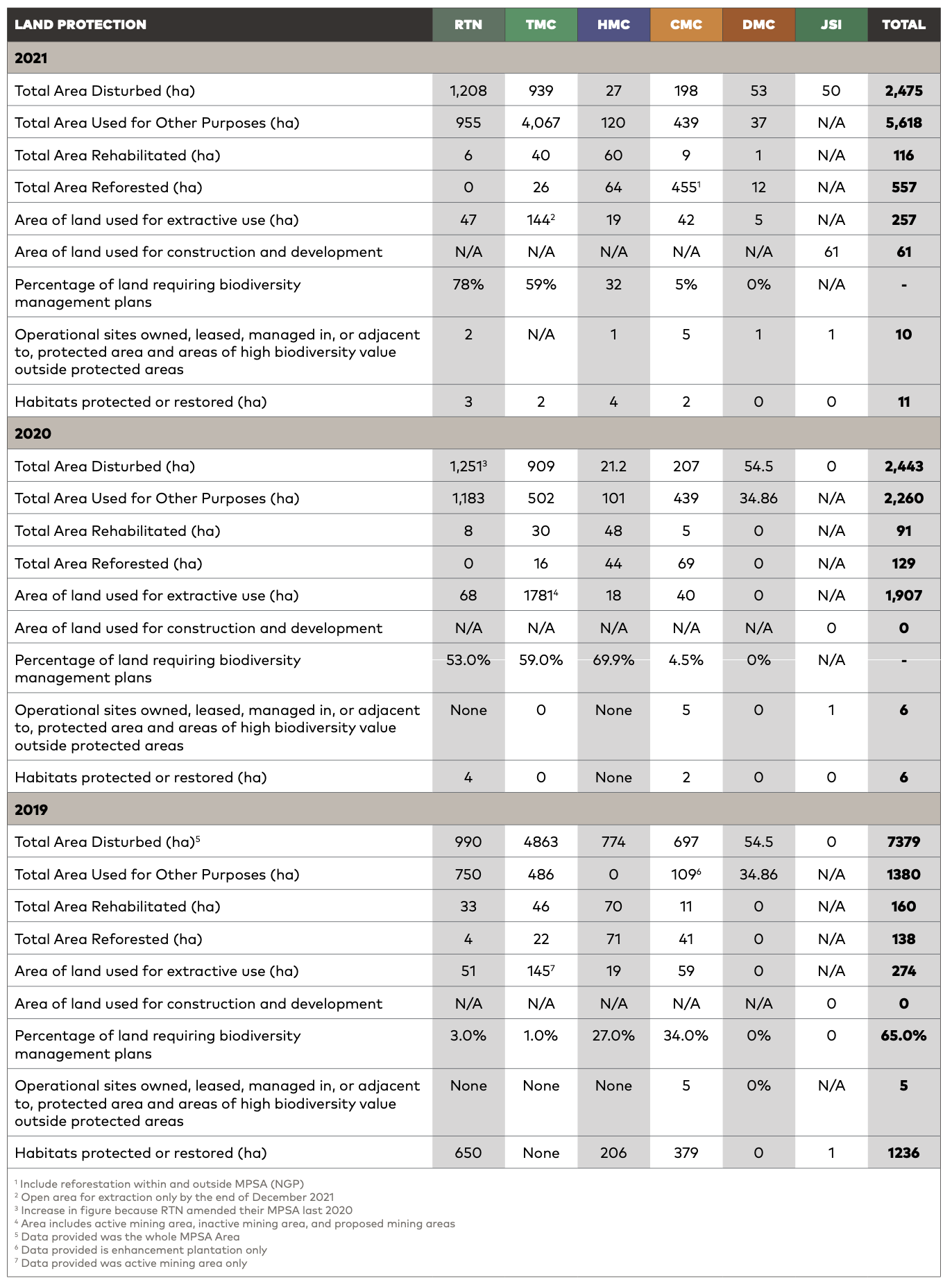

Land Protection

NAC takes pains to protect biodiversity in its areas of operation, recognizing the importance of natural habitats to various flora and fauna species, some of which are included in the IUCN Red List and national conservation list. The Company, therefore, implements consistent practices as mitigating measures, such as:

- Proper handling of cleared vegetation, including topsoil management

- Acquisition of Special Tree Cutting and Earth-balling Permit (STCEP) for earth-balling projects and strict compliance with the requirements

- Progressive rehabilitation of mined-out areas and reforestation with indigenous species to preserve the natural floral biodiversity of the affected sites

HMC’s Biodiversity Management is a major component of its AEPEP that supports the following programs: Buffer Zone establishment, reforestation inside its MPSA, accreditation of DENROs, conducting flora and fauna assessment, as well as ongoing initiatives such as establishment of mangrove plantation, coral nursery, and artificial coral reefs.

RTN also has numerous environmental programs, which include “Towards 5 Million Trees for Palawan”, “Edible Landscaping Contest v.2”, “Adopt a Tree, Make a Legacy,” Project, progressive rehabilitation using native and endemic tree species, and monthly inhouse biodiversity monitoring and observation. CMC continued its support on biodiversity conservation through funding for conservation initiatives and the deployment of Bantay Gubat and Bantay Dagat. On the other hand, DMC’s initiatives included National Greening Program with the DENR covering an area of 12.1 hectares.

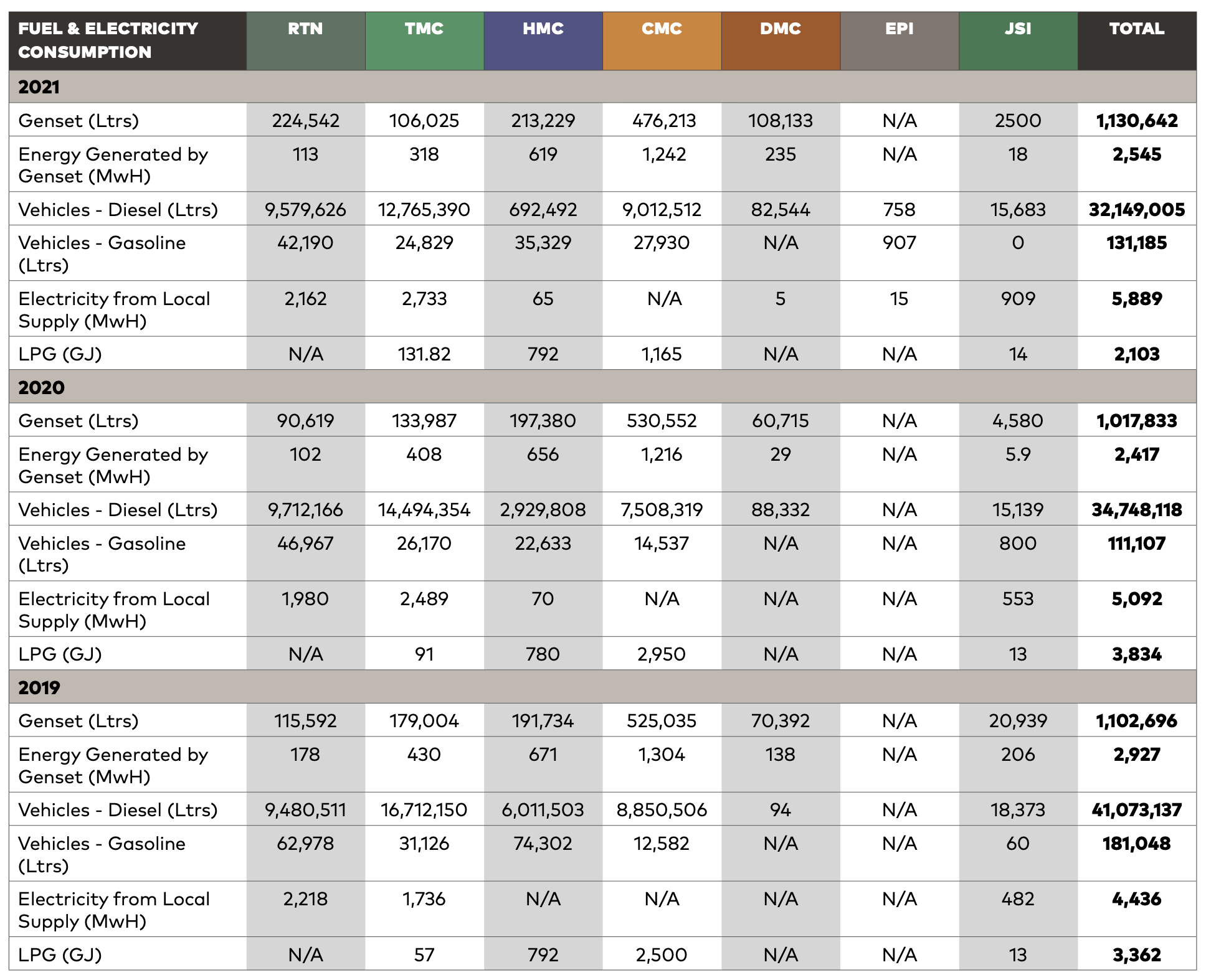

Energy Consumption and Management

Efficient use of resources combined with practical resource management plans implemented with care was the approach NAC used as it aimed to reduce overall energy consumption across the organization.

In 2021, TMC continued the use of the more fuel- efficient Articulated Dump Trucks (ADT) and the use of its conveyor belt system that reduces the need for a trucking system in ore hauling. Mine yards were relocated to reduce haulage distance. With the conversion to LED lights across its operations, its gensets operating hours amounted to only 20% of its overall consumption.

HMC chose to use LED-type equipment for all lighting needs of its facilities. The efficient adoption of such equipment helped reduce long-term costs and maintenance. Furthermore, HMC has adopted the use of solar technology as an alternative source of power for streetlights. HMC’s power reduction program was supported through guidelines on scheduled operations of the gensets to optimize usage with identified peak and off-peak hours to generate minimal power consumption.

DMC also used the same strategy of optimizing genset use based on the load requirement. It has three gensets available. The 125KVA genset will operate when the load or power demand is minimal, while the 569KVA is to supply and meet the power demand during day operation (peak load), all offices, accommodations, Assay lab, Sample prep, core house, Motor-pool, and warehouse. On the other hand, CMC managed consumption by lowering shipment numbers per year and monitoring and controlling fuel utilization through carpooling services for employees’ service transport.

The pandemic situation had an impact on all these conservation efforts. Due to the government workplace restrictions, temporary work scheduling was enforced, and this included night shifts as part of the adjustment during the lockdown period. Another challenge was the upkeep and comprehensive maintenance system for gensets to ensure reliability as the equipment ages. Gensets require regular and proper maintenance to be in good running condition and prevent performance and efficiency loss.

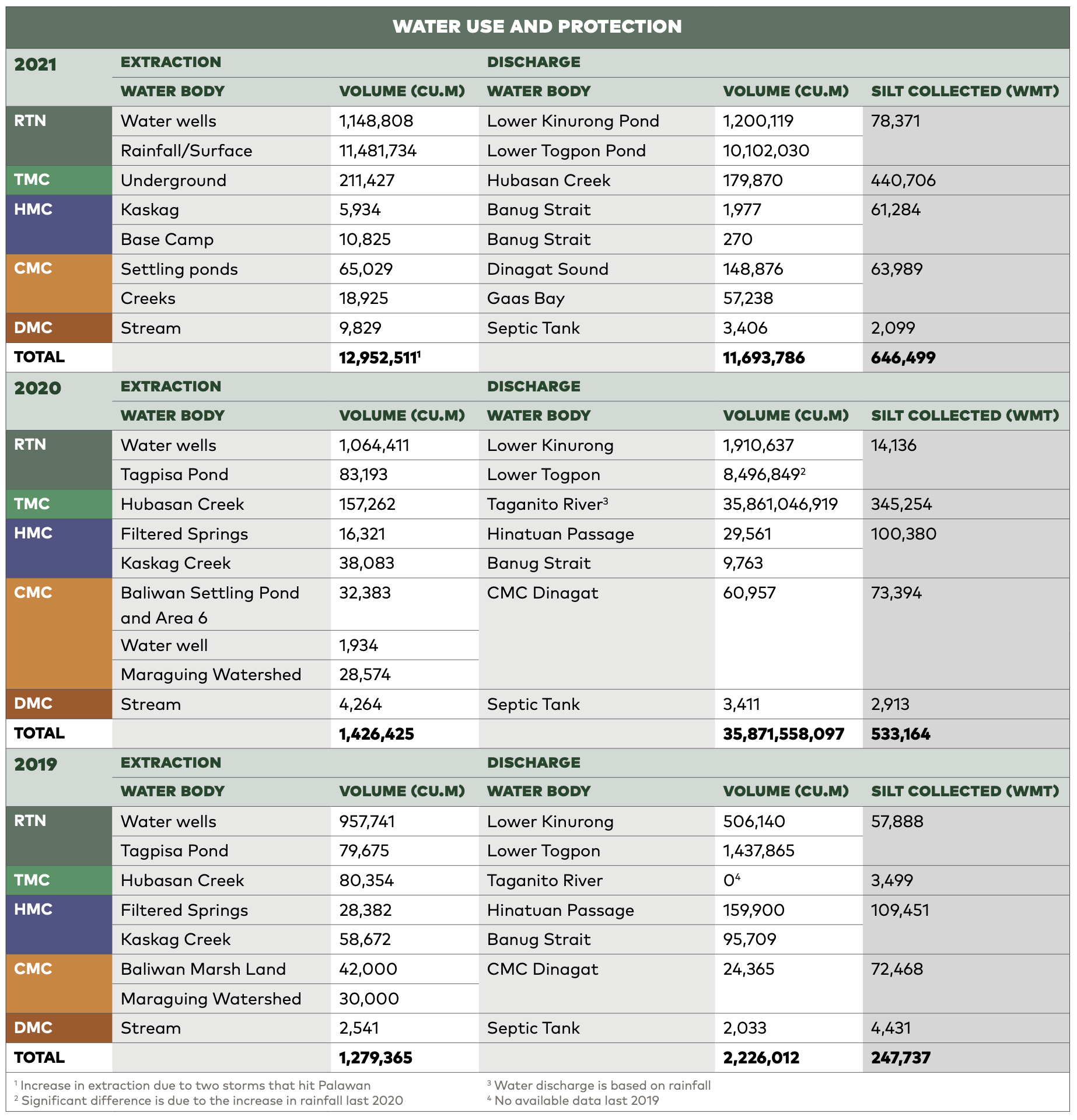

Water Use and Discharge

The EMS also enables the NAC to identify facilities and activities that pose a threat to groundwater. Hence, each mine site has a water management plan, supplemented by several policies and practices on water conservation. Among the processes in place are:

- Monthly and quarterly physical and chemical monitoring of Total Suspended Solids (TSS)

- Establishment of activated carbon gabions

- Regular dredging of sumps and ponds

- Planting of slopes to reduce exposed areas

- Vetiver grass planting in ponds for phytoremediation

- Using oil-water separator to prevent contamination

- Covering of ore stockpiles to minimize silted water

- Generation from stockpile areas

- In-house water sampling

- Emergency response procedures for accidental releases of contaminated water

- Construction of a drainage system that directs water/leakages to designated areas of treatment

Water use and discharge were regularly monitored, and proper mitigation measures were implemented for known risks. The landfill, for instance, is layered with high-definition polyethylene to provide impermeability and containment of contaminated water. Also, wastewater undergoes filtration through silt curtains and silt containment ponds and was then reused for dust suppression activities and product washing.

RTN also installed a rainwater harvesting facility for toilet use at its Admin Building, conducted desilting and installation of desilting pads on three (3) siltation ponds for more water attenuation and water recycling. Improvements were made to the spillway of Lower Togpon Pond, that further initiated the innovation proposals for possible water efficiency programs in 2022.

TMC conducted maintenance on settling ponds by desilting a total of 440,706 cubic meters, with new sumps constructed on active areas to initially collect silt carried by run-offs during rain. Meanwhile, HMC installed surfactant traps at its laundry facility and grease traps at its kitchen areas to intercept most greases and solids before entering a wastewater disposal system.

DMC took steps to identify improvements to water lines for implementation under its approved 2022 budget. Similar to the other subsidiaries, DMC continued to encourage employees and guests to conserve water and be conscious of water consumption. Signage and posters in strategic areas remind people to turn off the faucet when not in use.

Below is the individual Effluent policy of NAC and its operating mining companies

Effluents_AEPEP_RTNMC

Effluents_AEPEP_TMC

Effluents_AEPEP_CMC

Effluents_AEPEP_HMC-TNP

Effluents_AEPEP_DMC

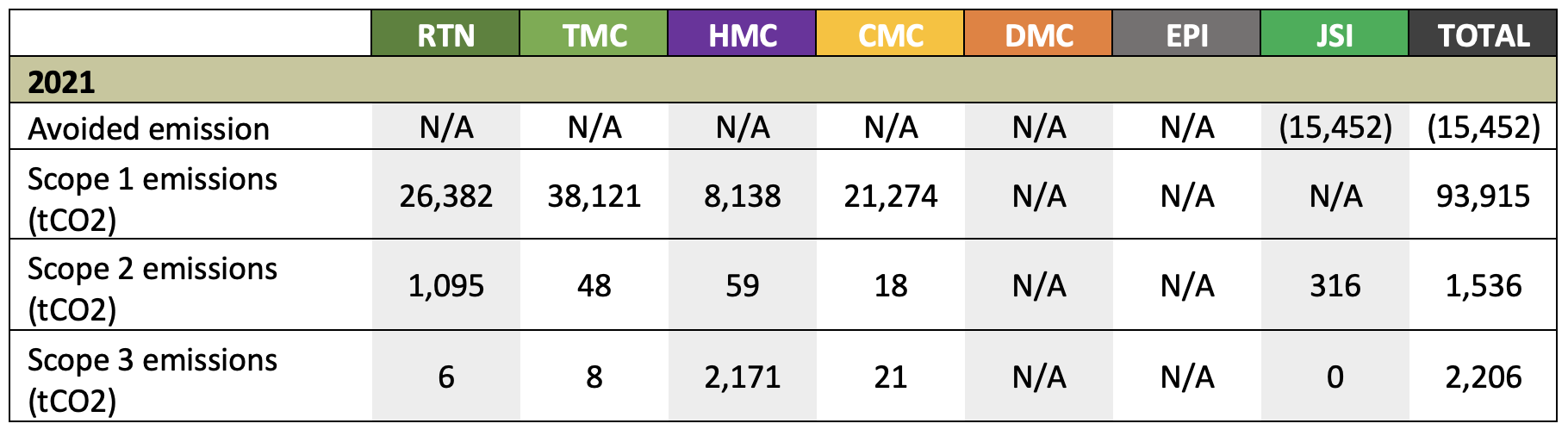

Air Protection

NAC’s operating mines conduct regular emission testing and measurement of dust emissions to ensure compliance with all air quality regulations. In addition, the Company has also acquired necessary permits for pollutant- emitting devices and provided monitoring reports to DENR agencies that assured emissions are well within the regulatory limits.

RTN consistently conducted stack emission sampling of new air pollutant sources. As a result, RTN identified fugitive dust as the primary emission from its operation. The Company used additional water trucks for road watering and acquired a road vacuum sweeper. Meanwhile, TMC deploys water lorries to designated strategic areas to address dust excesses and integrated a new contract requirement for its contractor specifying the provision of water lorries to help address dust issues.

In addition, the NAC Technical Working Group (TWG) and Economic, Social, and Governance (ESG) team required each subsidiary to submit 5-year historical baseline of GHG emissions. A training on GHG Inventory was also conducted to update and harmonize the tools and methods being used by the subsidiaries.

In support, RTN conducted baselining of certain forest areas to determine sequestration capacity and potential emissions once disturbed and used for mining activities.

And for its part, EPI conducted an in-house inventory of its GHG emissions based on the streamlined standards and is collecting historical baseline data as a reference for its ongoing assessment and gap analysis. After this analysis is completed, EPI can move forward to strategically design plans to manage Scope 2 emissions which may include the use of renewable energy sources or leasing biofuel/ renewable energy-based equipment.

GHG Emission

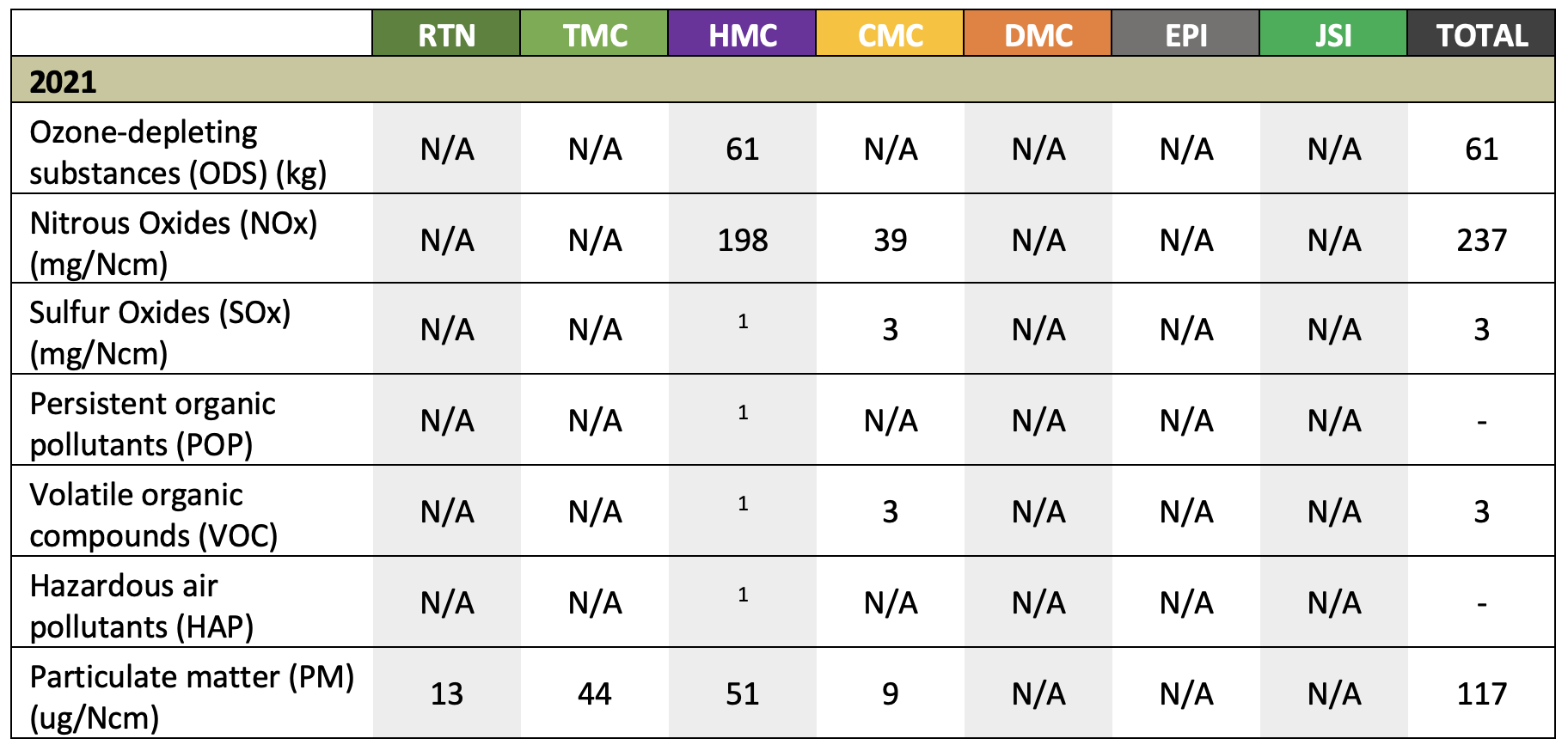

Non-GHG Emission

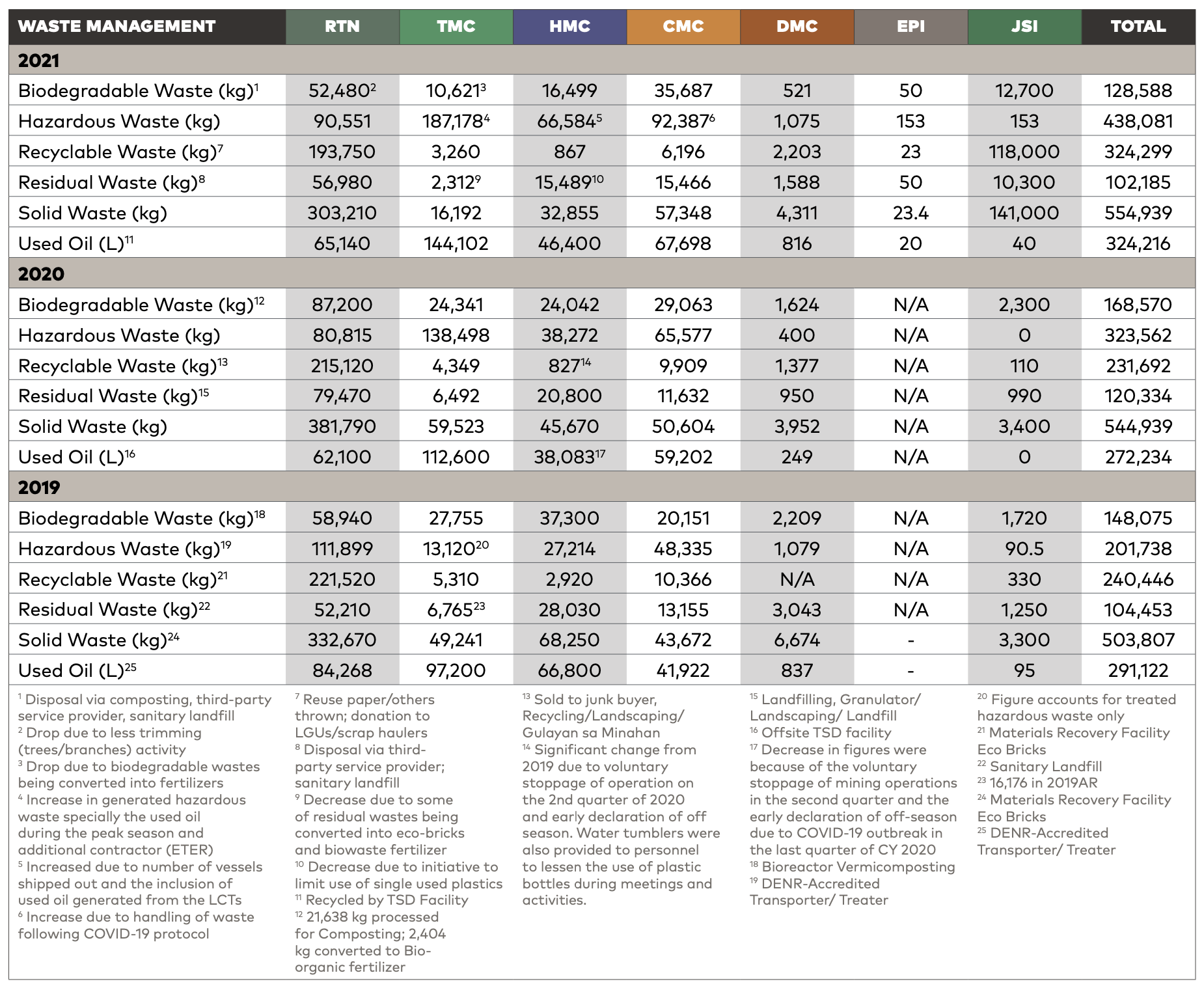

Waste Management

As a responsible corporate citizen concerned not only for the environment but also for the health and safety of its people, NAC fully supports the global campaign on reducing waste. Accordingly, the Company conscientiously implemented an effective solid waste management plan.

Furthermore, NAC supports the principle of upcycling, seeing great value in technologies that help the Company manage wastes effectively, such as DOST’s bioreactor, vermicomposting, and mulching for biodegradable wastes; the use of Materials Recovery Facility (MRF) for recyclable and reusable wastes; and the use of sanitary landfill for residual wastes.

Additional initiatives by the operating mines include TMC’s purchase of a shredder machine to fragmentize residual and plastic waste, which are then transformed into eco- bricks. TMC also processes biodegradable waste in the biofertilizer maker machine to eventually mix with ameliorated soil.

HMC has also intensified the production of bio- organic fertilizers from biodegradable kitchen wastes and the practice of vermicomposting. In addition, it initiated the establishment of Biogas Digester Facility to accommodate all kitchen wastes, especially food wastes. Also, the Company continued using Jobo Pots in the nursery operations. For such efforts, HMC saw a reduction in solid waste generation of about 28% for 2021 compared to the previous year.

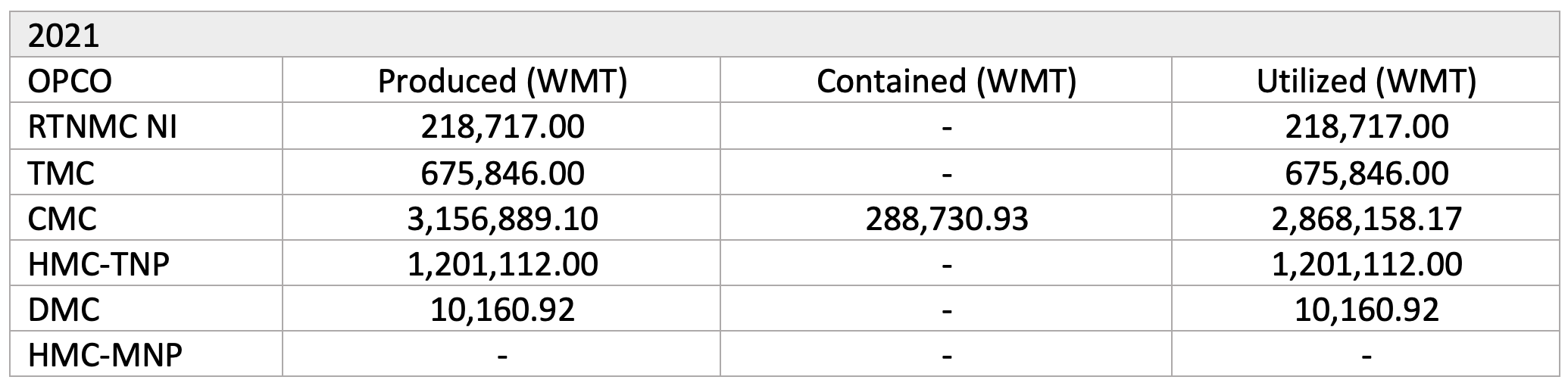

Mineral Waste Management

In compliance with DENR Memorandum Order No. 99-32 Series of 1999, the operating mining companies of the NAC Group implement the management of mine waste guided by current best practices committed to ensuring control over the impact of mine waste and efficiently protecting the environment. It is also undertaken with emphasis on economic and environmental considerations, as well as safety, health, social, and cultural concerns. The common method of utilization of mine waste among the operating mining companies is to fill materials used for surface mining openings, roads, and mine rehabilitation.

Data extracted from the Semiannual report on Mine Waste and Mill Tailings Produced, Contained, and/or Utilized of the operating companies of NAC Group

Climate-related Risks and Opportunities

NAC advocates for responsible mining as we recognize how we are all connected. We appreciate that our synergetic relationship with our communities and our environment impacts both short- and long-term.

With the governance and leadership of the Board of Directors and the management team, our Enterprise Risk Management (ERM) system helps us establish proper measures for the identification, assessment, and management of risks that may affect the Company.

The risk management strategy addresses climate-related risks and identifies action plans, persons responsible, and expected timelines to maintain the Company’s operations or reduce the duration of operation disruptions.

The risks were identified based on how they would impact our people’s safety, the supply chain, the reliable energy supply, and the unhampered logistics in and out of mine sites. Integral to the ERM is preparing both people and facilities for emergencies, the training of emergency responders, the provision of equipment and technology, and the redundancies for physical systems.

NAC works with the rest of the industry players, its host communities and nearby communities, and government agencies and regulators, toward building resilient and sustainable communities. In addition, the Company is proactively working to protect shared natural resources that would benefit future generations.